What is gasoline particulate filter (GPF) and how does it work?

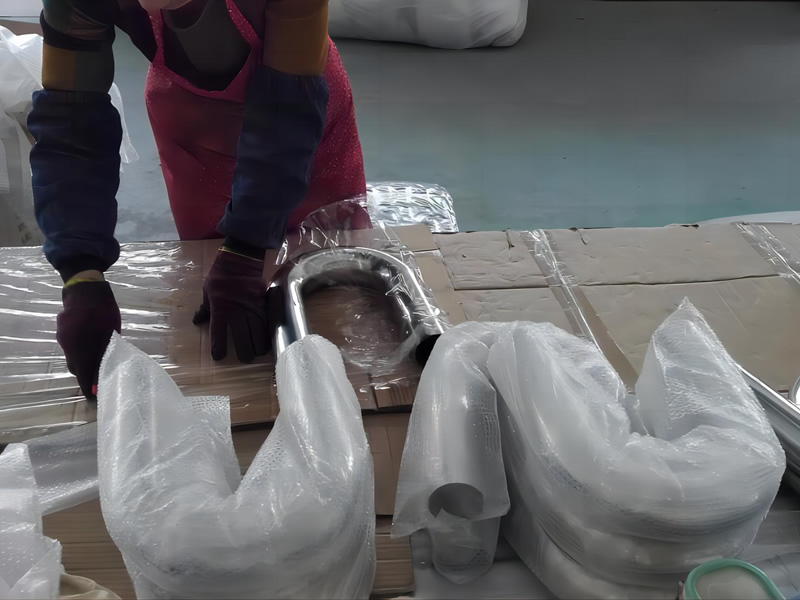

What is GPF? Automobile GPF refers to gasoline engine particle filter. GPF is a ceramic filter installed in the exhaust system of a gasoline engine. The shape is a cylinder, which is no different from